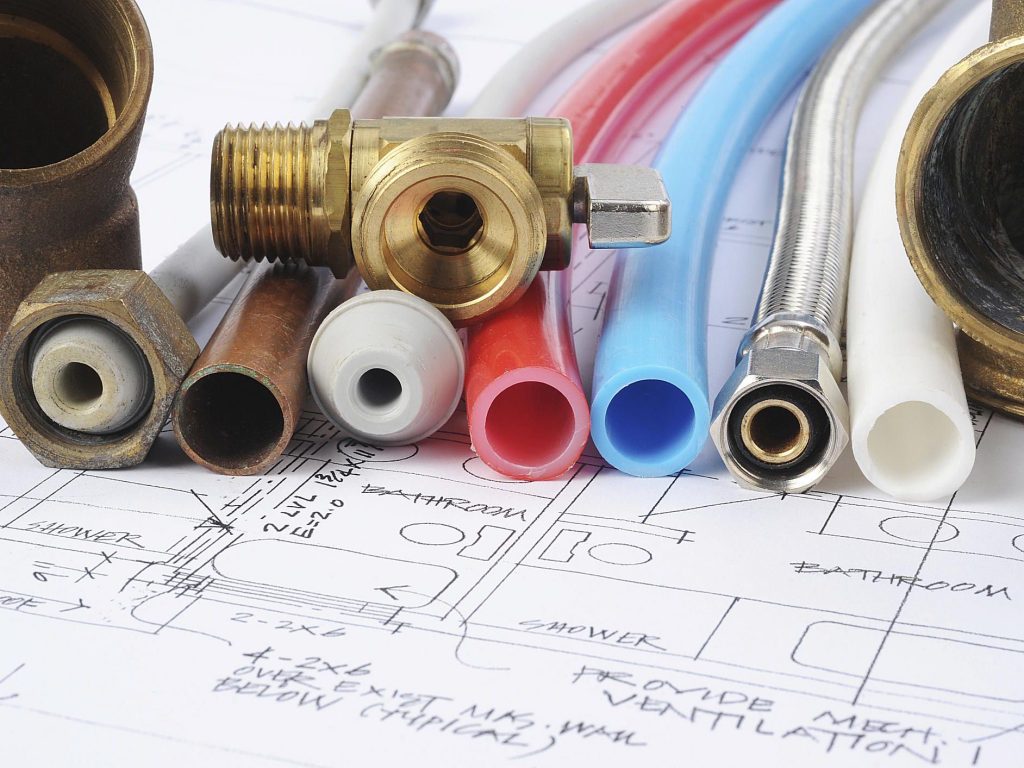

When planning your next plumbing project, you need to examine the numerous kinds of pipelines for the job. Although stainless steel and brass tubing could be used, many projects will be completed with galvanized metal, copper tubing, or some sort of plastic pipelines for plumbing applications.

Lead pipelines and lead solder used on copper pipelines have actually been outlawed considering that 1986, so any new pipes projects should not cause more issues with lead poisoning, although some kinds of plastic might absorb chemical contaminants coming from the water supply. According to Chemical & Engineering News, all kinds of pipe materials can impart taste and odors to drinking water, which frequently can be alleviated by flushing the system.

Benefits of Plastic Pipe

Plastic piping can be made of PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), or PEX (cross-linked polyethylene). In general, the plastic pipeline doesn’t rust or corrode, is light in weight, easy to cut and easy to sign up with– no welding required.

PVC piping is an excellent, inexpensive option for many plumbing tasks. It is easy to install, with a series of various techniques for joining, such as clamps, mechanical couplings, or solvent welding. PVC outside lines can be buried, though they may need additional care to avoid collapse. The main downside of using PVC piping is that it can’t hold up against high temperatures. This suggests you can’t utilize it for hot water lines and it’s not ranked for drinking water, due to possible heat destruction of the plastic.

CPVC pipeline has all the benefits of PVC pipe, plus the included chlorine gives it a higher heat resistance. It is likewise rated for drinking water, and is versatile, fire-resistant, and well insulated to prevent energy loss for either hot or cold water.

PEX tubing resists high heat and is frequently used for glowing hot water heating unit and drinking water lines, though it can’t be straight connected to a warm water heating system and requires a short area of copper tubing in between. It is extremely versatile, so it can be quickly installed through walls and around corners. PEX lasts for years and endures freezing temperature levels well, resisting fractures due to freezing and thawing of water in the lines.

Advantages of Metal Pipe

Historically, the majority of piping was made from brass, copper, cast iron, or some other metal. Brass and copper have innate rust resistance, which makes them outstanding choices, however even these have seen issues when the pipes begin to age over decades, often due to lead in the solder used to link them.

One of the most widely used materials on Earth, steel provides outstanding strength, durability, and toughness. It is a versatile, cost-effective solution for water/sewer pipes and pipeline systems.

Galvanized Steel Pipe vs. Black Steel Pipe

Galvanized steel pipeline features a protective zinc coating that helps avoid deterioration, rust, and the accumulation of mineral deposits, consequently extending the pipe’s life expectancy. The galvanized steel pipeline is most typically used in plumbing and other water-supply applications. In addition, galvanized pipes are a lower expense option to steel, and can attain rust complimentary defense for up to 30 years while maintaining similar strength with a resilient surface covering.

Black steel pipeline contains a dark-colored iron-oxide covering on its entire surface area and is used for applications that do not require galvanization security. The black steel pipeline is used mainly for carrying water and gas in rural and city areas and for providing high-pressure steam and air. It is typically utilized in a fire lawn sprinkler thanks to its high heat resistance. Black steel pipeline is likewise popular for other water transfer applications, including drinkable water from wells, as well as in gas lines.

304 Stainless Steel Pipe

304 stainless-steel pipelines also can be utilized for transporting liquids. Stainless deals high deterioration resistance, remarkable durability, high strength-to-weight ratio, fair resistance to thermal and electrical conductivity, ease of fabrication, ease of cleaning, and it is non-magnetic and harden-able by cold working.

Brass Tube/Pipe

Though brass piping is older material, it’s still utilized today for water supply and drain lines, as well as gas lines. Brass, an alloy made of copper and zinc, is extremely resistant to deterioration, and as long as a lead-free brass alloy is chosen, it must be safe for drinking water. Because it is a relatively soft metal, brass tube/pipe can be installed with a tight seal, preventing leaks.